Doclean™ Road Sweeping Brush Filament Performance

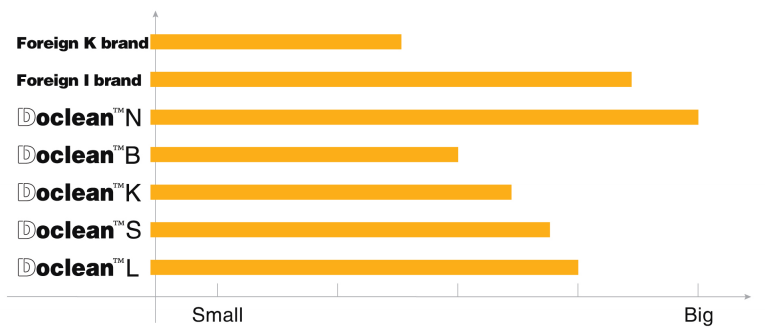

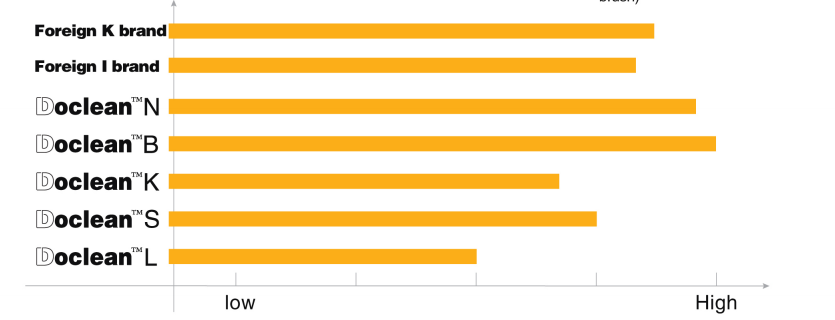

1. Bending Strength

Bending strength means the hardness and softness of filament. Filament with greater anti-bending force has better cleaning effect corresponding to the reaction force, and the filament is more easy to sweep the larger volume of garbage quickly.

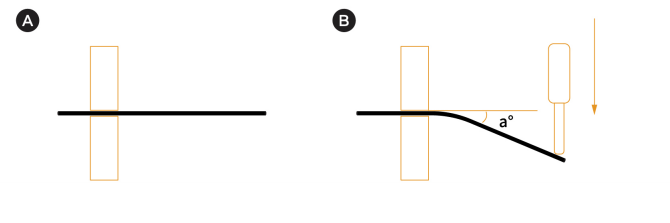

Bending Strength Test Procedures:

Fixing the upper part of filament, and then pushing the lower part of fiber to the fixed position by a push-pull meter to test the bending strength.

Filament with greater anti-bending force has better cleaning effect corresponding to the reaction force, and the filament is more easy to sweep the larger volume of garbage quickly.

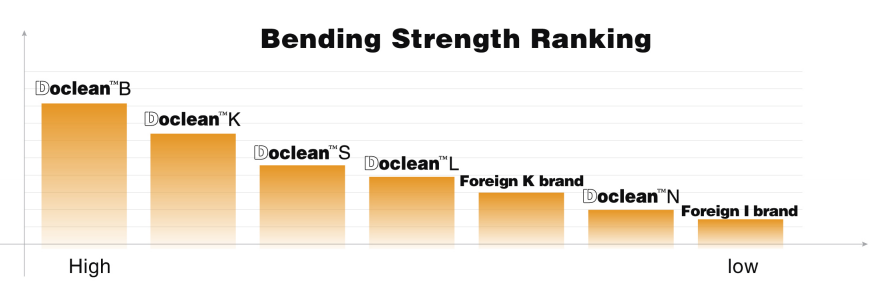

2. Breaking Resistance Rate

It means filament do not break under the certain external force. Breaking resistance rate of filament will directly influence the working efficiency and cost in the tuft process.

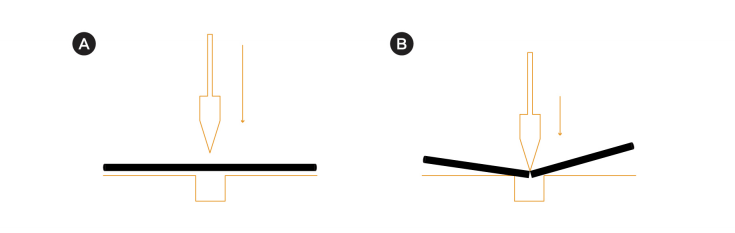

Breaking Resistance Rate Test Procedures:

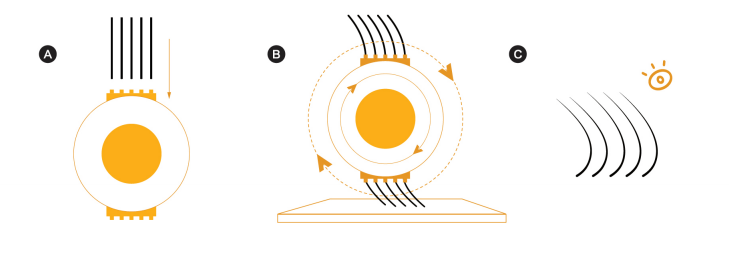

Putting one filament on the plane with a hole at the lower end, and that filament is rapidly impacted vertically downward with a fixed force right above the hole. That test procedures can simulate the process of fixing the folded filament in the hole with a rivet by external force. The test procedures can check whether the filament is broken under the impact force. Please see the following picture:

Filament with greater breaking resistance performance is not easy to break under the specific condition in the tuft process, which improves the yield and the use effect of the finished products.

3. Anti-fatigue Performance

Plastic will occur fatigue failure when it is subjected to repeated or periodic load. The failure form is the attenuation of mechanical properties, which will cause cracks and finally lead to the complete structural damage. The fatigue life of plastic is defined as the numbers of stress actions required to destroy the samples under the action of stress level. The lower the stress level, the longer the fatigue life.

Anti-fatigue Performance Test Procedures

A. Fixing the filament on the machine and setting up data of load force values and friction times.

B. Operating the machine. Under the load conditions, filament rotates and rubs repeatedlyin the machine to simulate the working state of filament in the sweeping process.

C. After test, observing the degree of wear ofBrush Filament.

The stronger anti-fatigue strength, the lower the wear rate of the filament. In the long-time high-speed frictional cleaning work, filament is not easy to deform and fall off, which can reduce the frequency of replacing the sweeping brush.