How to produce good quality filament for the gel polish brush?

How to produce good quality filament for the gel polish brush? Do you know that?

Many gel brush manufacturers found that the bending recovery strength of the finished gel polish brush was unsatisfactory after the tufting process. Do you know about the reason?

In order to find the reason, Tai Hing`s R&D team carried out ` the bending strength test of monofilament & whole brush` and studied `the filament tufting technique and fixing method of gel polish brush`. Finally, Tai Hing would provide the best filament solution for gel polish brush manufacturers.

1.Monofilament Bending Recovery Strength

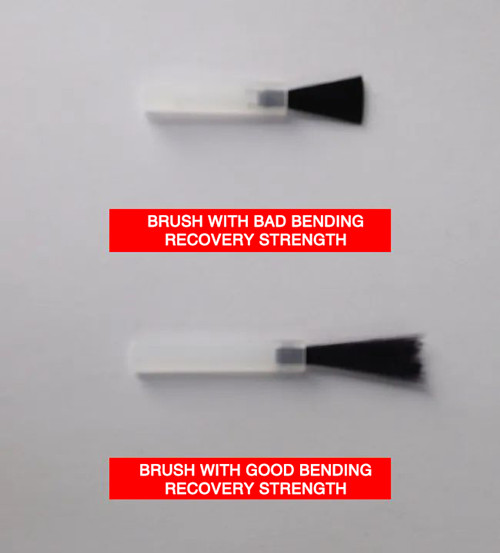

First, we prepared A gel polish brush with bad bending recovery strength and the B gel polish brush with good bending recovery strength.

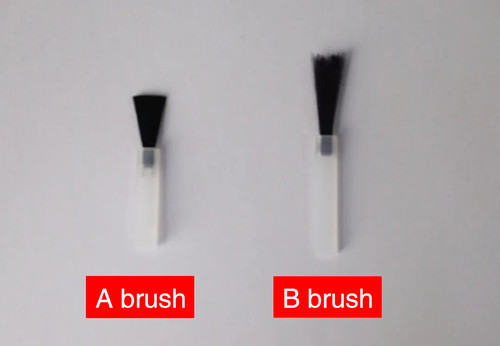

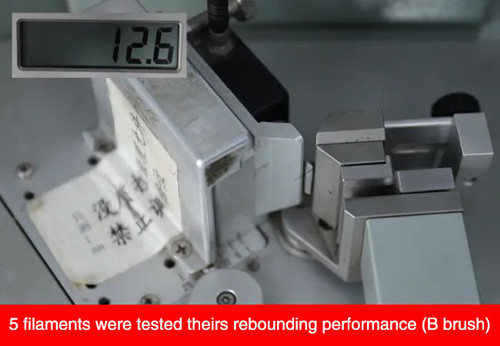

Then, taking out 5 filaments from A brush and B brush respectively.

After bending recovery strength test, A filament was similar to B filament in terms of rebounding performance. That meant there was no difference in the hardness and rebounding performance of A and B filament.

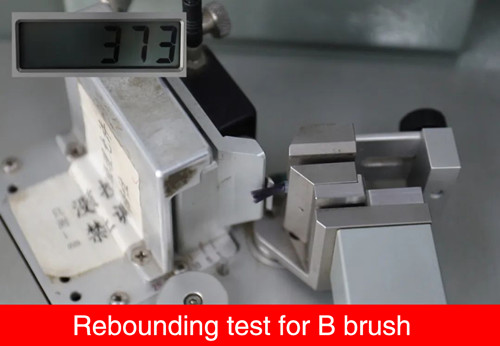

2.The Whole Brush Bending Strength Test

We continued to carried out the bending strength test of A filament bundle and B brush bundle, in which we found that the bending strength of B filament bundle was 29% higher than A filament bundle. Why was there no difference in data between A and B single filament? Why was there the difference in data between A and B filament bundle? The reason was the different filament tufting technique of A brush and B brush.

3. Professional Analysis

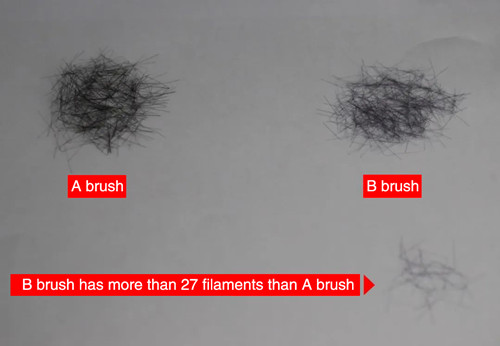

We took apart A brush and B brush. After counting the filament number of A brush, we found that B brush had more than 27 filaments than A brush.

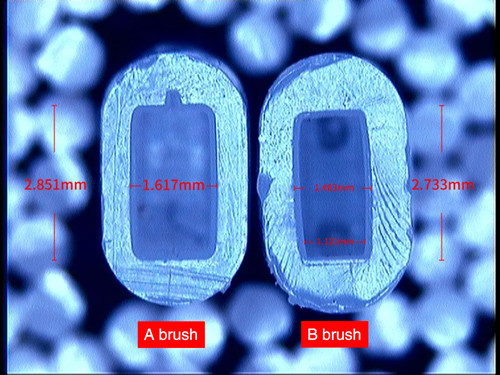

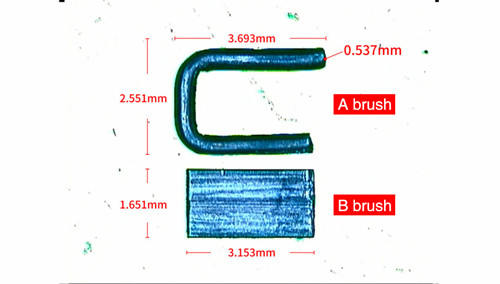

Comparing other brushes of A and B brush, we found that there was a difference of 7% in the average number of filaments of A brush and B brush. Next, we observed the pore size of A and B brush through the microscope, in which the pore size of B brush was 11% larger than the pore size of A brush. The pore size of B brush could accommodate more filaments. The following picture of two kinds of pore size was as below:

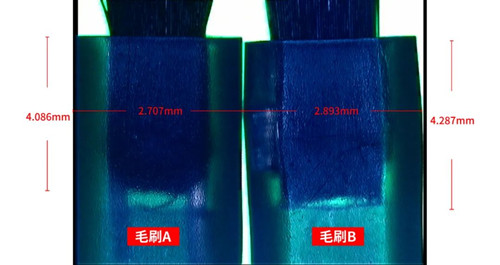

Besides, the average tufting thickness of B brush was about 11% greater than that of A brush. Therefore, B brush could be tufted more filaments and its bundle filaments were more thicker.

B brush will provide you more elastic toughing experience when you move the bristles horizontally.

There was the difference of the fixing method in filament tufting process between A brush and B brush. B brush used one small steel plate while A brush used an U-shaped iron wire. Through measurement, it was found that the volume of steel plate was smaller than that of U-shaped iron wire. Therefore, B brush can be tufted more bristles.

4. Summary

The bending recovery strength of gel polish brush is influenced by the tufted brush filament quantity and the structure of plastic adhesive component. Gel polish brush manufacturers need to adjust the shape and pore size of plastic adhesive parts of tufting process, which ensures more bristles can be tufted into the pore size and the brushes have better bending recovery strength effect.

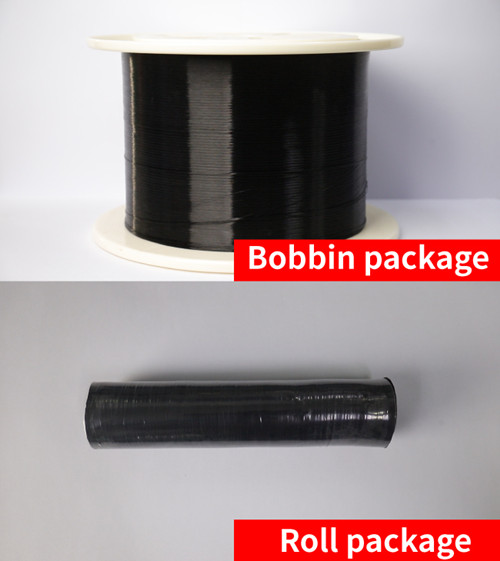

Tai Hing`s gel polish brush filaments have excellent bending recovery strength effect, filament straightness and uniform diameter, which can reduce the marks during the painting process. Filaments have good tensile strength, not easy to deform after the long-term use. With strong chemical resistance, filaments have good color fixation performance. Tai Hing provides gel polish brush filament product in two packaging methods of roll and bobbin package for customers.

Sales manager`s wechat QR code is as below. If you are interested in our Wetrans filament, please feel free to contact Peter, thanks.