Do you know how to choose suitable filaments for steel washing brush roller?

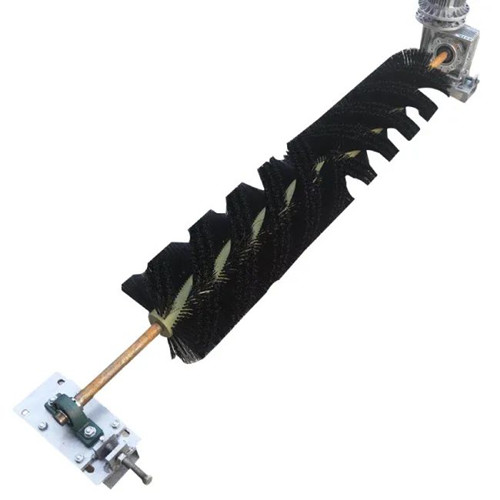

After deep processing, metal workpieces surface will be covered by dust and oil, which is difficult to be cleaned. In order to solve that problem, the steel washing roller brushes play the important role in that washing process.

Why the roller brushes are so important?

Filaments for steel washing roller brush have outstanding washing effect to remove the dust and oil on the metal surface.

In washing process, the brush rollers need to rolling continuously in the machine to wash the steel surface repeatedly with spraying water. If the brush roller filaments are too hard, the brush will scratch the steel surface. Otherwise, if the filaments are too soft, the brush has bad cleaning effect.

Steel washing brush filaments usually have following features as below:

1. Better wear resistance, moderate hardness, better bending recovery strength, anti-corrosion and anti-aging performance;

2. Adaptable for harsh environment, such as acid washing, alkali washing, water brushing and hot water washing etc;

3. High rigidity, not easy to shed and deform. Durable for washing steel industry.

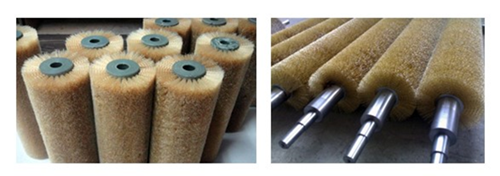

Tai Hing`s Steel Washing Brush Roller Filaments Introduction

Tai Hing focuses on developing and manufacturing high-end brush filaments, producing nylon612/66/6 fiber and PP bristles. Tai Hing`s brush filaments have excellent performance in industrial washing environment, such as acid washing and alkali washing working environment.

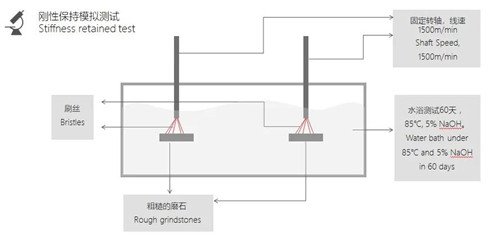

Slowing down Hydrolysis Reaction:

Tai Hing`s filaments can effectively slow down hydrolysis reaction in acid or alkali environment, and extend the service lives.

Low Wear Level:

brush filaments have excellent wear resistance. Even under high load and high-speed operation, filaments have low wear level to ensure the durable working effect for the long time.

Durable and Long-lasting:

our filaments have durable using period over half past two months through strict quality control and other testing. It can effectively reduce the frequency of changing brush rollers and therefore increase the working efficiency.

Tai Hing Filaments for Brush Roller Performance

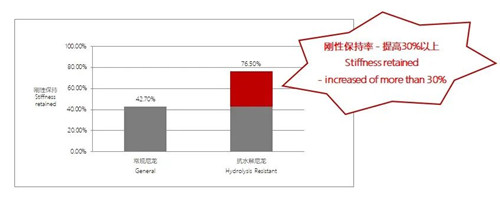

High Rigidity:

Filament stiffness has increased over 30%, and the rigidity decline level is lower than other common monofilament in industrial washing environment.

Stable Mechanical Property:

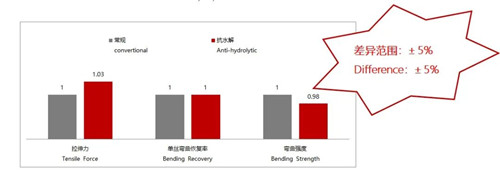

Filaments added effective anti-hydrolysis component retain over 95% excellent performance of original filaments.

Sales manager`s wechat QR code is as below. If you are interested in our Wetrans filament, please feel free to contact Peter, thanks.

Email: marketing@taihingnylon.com