What is the suitable winding method for filaments with bobbin package?

Common Filament Package

In the market, there are two filament winding methods in filament industry. For example, the one is spool winding method, the other one is triangular frame winding method. Filament with bobbin package refers to the first winding method, which ensures that filament can be retracted fully after the stretching process. We can also adjust the filament length based on customer`s requirements.

In order to ensure the excellent filament straightness, Tai Hing carries out two standards for filament winding process. Tai Hing adopts spool winding method for filaments with less than 0.4mm diameter, while adopting triangular frame winding method for filaments with more than 0.4mm. We must use spool winding method for crimped filaments to ensure the uniform curvature of crimped filament.

The Advantages of Bobbin Package

Bobbin package has advantages of neat filament winding and convenient filament tufting. It does not need to additional workers to wind filament, which can greatly reduce the labor cost and improve the tufting efficiency. Besides, various spindle size filaments with bobbin package meet different filament usage of tufting machines.

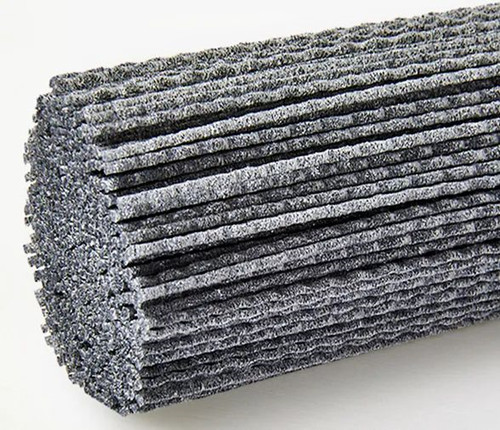

New Product-GrindFil-B Abrasive Filament Bobbin Package

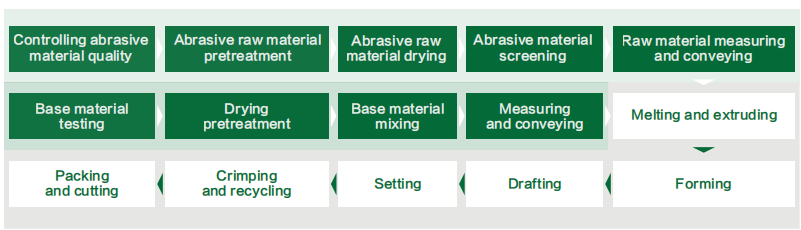

GrindFil-B abrasive filament is made of high quality nylon 612/610/6 base material and silicon carbon/aluminium oxide grinding sand. It is manufactured through the production process of extrusion, draft and other processes. The production process flow chart is as below:

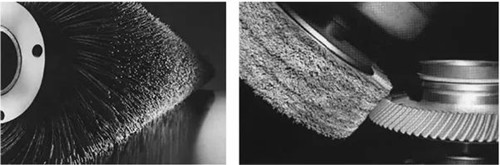

With strong grinding ability, GrindFil-B is widely applied in twisted brush, strip brush, belt brush, disc brush, roller brush, cup brush. Besides, GrindFil-B is also applied in wooden grinding, steel polishing, metal finishing, glass grinding and ceramics grinding industries.

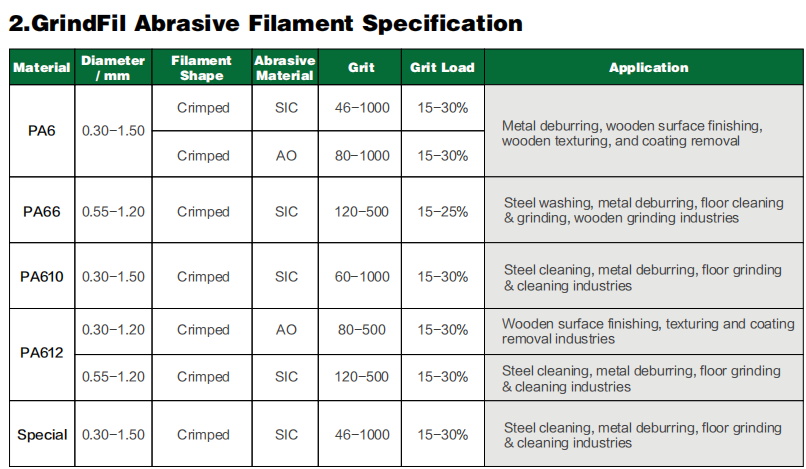

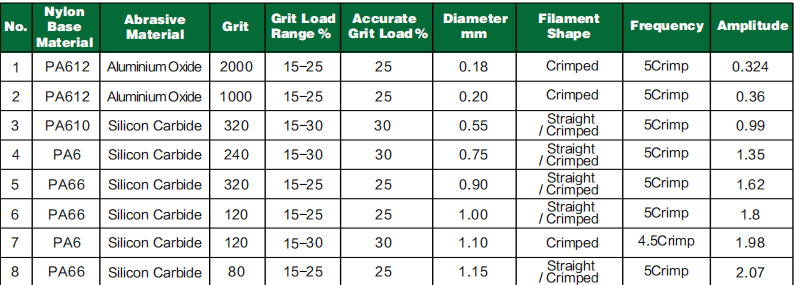

GrindFil-B Abrasive Filament Specification

GrindFil-B Performance

Uniform Filament Diameter&Neat Filament Winding

GrindFil-B abrasive filament has diameter range from 0.3mm to 1.5mm. Every filament has even and uniform diameter, meeting different grades of polishing&cleaning standards without causing any damage on workpieces surface.

GrindFil-B bobbin package has crimped frequency value from 0.54 to 2.7.

Excellent Bending Recovery Strength

Tai Hing has improved the manufacturing technique of GrindFil-B abrasive filament with bobbin package, strengthening its bending recovery strength. The monofilament bending recovery rate of GrindFil-B exceeds 30% through the rebounding test.

Good Toughness and Wear Resistance

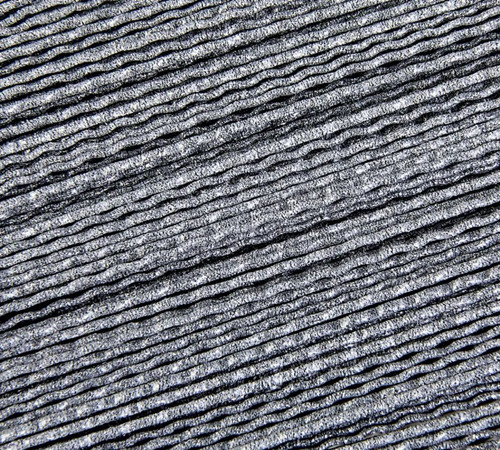

The specially treated abrasive material surface structure improves GrindFil-B performance of strong rigidity and wear resistance. With better performance of high toughness, GrindFil-B is more durable than other traditional filaments. GrindFil-B has excellent characteristics of stable chemical properties, wear resistance, anti-corrosion, higher straightness, and effective grinding ability. Durable GrindFil-B is not easy to deform and age.

Suitable for Different Environment

GrindFil-B has strong adaptability to deal with various problems easily in different environment. GrindFil-B keeps original abrasive material grit load in different environment, such as acid-base environment, chemical organic solvent, high or low temperature environment, wet or dry environment. GrindFil-B is never affected by environment and it is the professional filament for your products.

Sales manager`s wechat QR code is as below. If you are interested in our Wetrans filament, please feel free to contact Peter, thanks.