Cleaning Robot Brushes for Photovoltaic Panels Are Greatly in Demand

With the improvement of people`s living demand, industrial and residential electricity consumption is becoming more and more tense. In order to meet the demand for electricity, large-sale photovoltaic power plants have been built around the world. Compared to the increasingly exhausted and non-renewable fossil energy, light energy is more efficient, green and sustainable.

It was reported that a large amount of dust and dirt accumulated on the photovoltaic panels surface has been seriously influenced the absorption of sunlight and the conversion of electricity energy. The loss of photovoltaic energy generation efficiency caused by the dirt accumulation on photovoltaic panels surface ranged from 5% to 20%, even higher. Therefore, the daily cleaning for photovoltaic panels is very important.

Cleaning Robot Brushes for Photovoltaic Panels Are Greatly in Demand

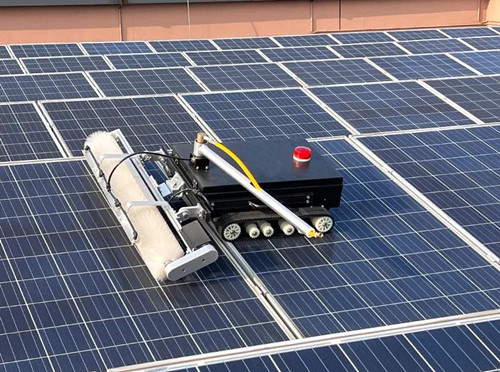

With the development of AI technology, Cleaning robot brush for photovoltaic panels has been launched. Dust and dirt on the panels surface can be removed efficiently from the bottom to the top through the rotating brushes and the blowing of the airflow.

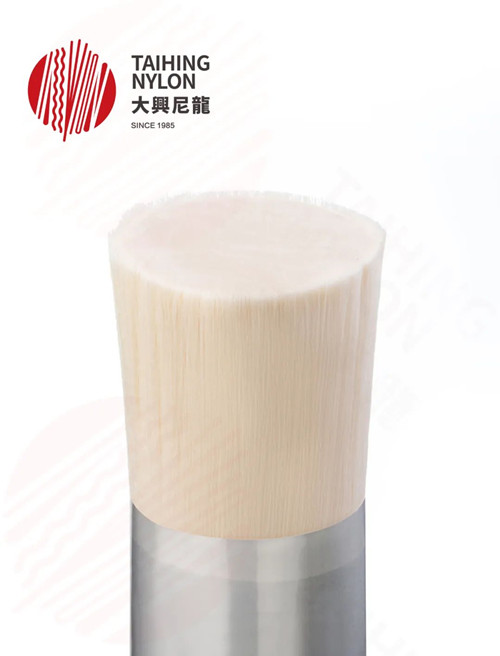

Professional brush filament is the important component of the cleaning robot brush. PP filament, nylon filament and PBT filament are the common material for the cleaning robot brush. These cleaning filaments have advantages of better bending recovery strength, wear resistance and chemical resistance etc.

Filaments for Photovoltaic Panels Cleaning Robot Brush

Tai Hing is a designated supplier of high-tech precise cleaning brush filaments. Our filaments strictly meet the softness, cleaning effect, and wear resistance standards for photovoltaic panels cleaning robot. Tai Hing provides Nylon6, PP, PBT filaments for photovoltaic panels cleaning, satisfying different degree of cleaning needs and protecting photovoltaic panels surface.

Filament Material Introduction

Nylon6 filament is smooth and glossy in texture, as well as resilient and great in bending recovery. It is suitable for fine cleaning industry.

PP filament has high filament toughness, durable service life, chemical resistance, and good wear resistance features. It is widely applied in common cleaning industry.

PBT filament is excellent in toughness. It also has great weather and fatigue resistant, high impact on strength, and great electrical property. With a wide range of applications, PBT filament is suitable for the open and sunny outdoor environments.

Available Functional Filament

At present, Tai Hing can add customized functions on the basic of nylon6, PP, PBT filaments, such as anti-UV , flame retardancy, anti-static, acid and alkali resistance etc.

Functions Introduction:

Anti-UV: better high-temperature resistance, weather resistance, and durable service life.

Flame retardancy: stable flame retardant effect by adopting UL V0 flame retardant material. Filament with flame retardant function will be self-extinguishing after ignition within 10 seconds.

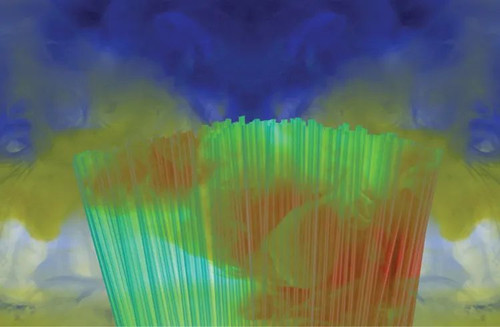

Anti-static: the conductivity of filament with anti-static function is less than 10^9-10^11Ω through the surface resistance test. It is effective to divert static electricity.

Acid&alkali resistance: filament has chemical stability, which can effectively slow down the speed of rigidity reduction, delaying the degradation of brush performance and extending filament service life.

Sales manager`s wechat QR code is as below. If you are interested in our filaments, please feel free to contact Peter, thanks. You can also contact us by email: marketing@taihingnylon.com