What Will Affect the Filament Tufting Effect of the Brush Making Machine?

In the brush manufacturing industry, the automation level of brush making machines has been higher. Many brush manufacturers purchased high-speed multi axis filament tufting machines, which greatly increased the brush making efficiency.

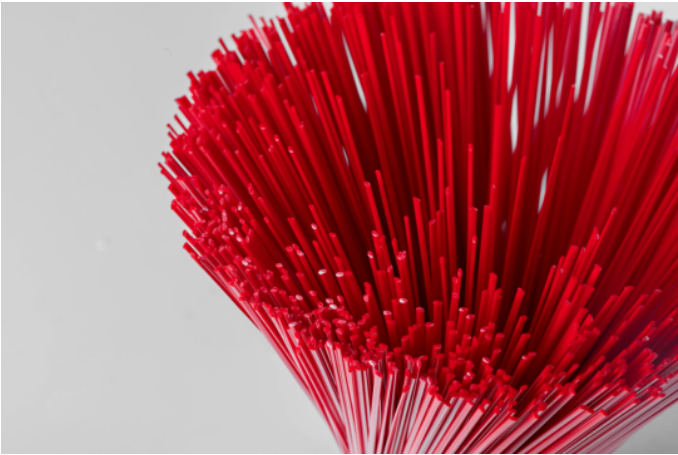

Filament Materials:

Nylon filaments and synthetic bristles with good resilience and tensile strength are the suitable choices, such as nylon filaments, PBT, PP, PET synthetic fiber etc.

These monofilament can withstand high-frequency bending and stretching action during the tufting process in different environment. For example, high quality filament are applied in personal care brush products, household cleaning brushes and industrial brushes.

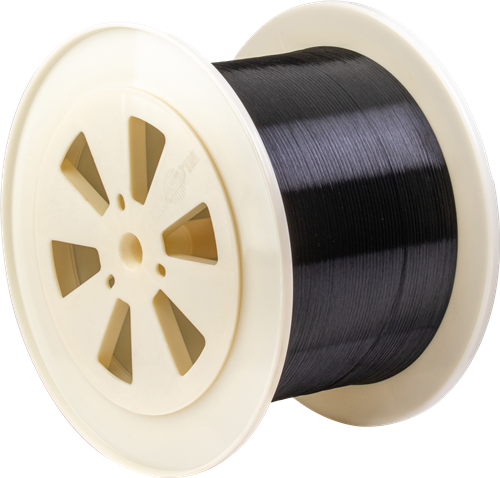

Uniform Diameter:

Filament diameter should confirms to the strict specification standards. Every diameter should be even and same. Uniform diameter increases the success rate of filament tufting process and avoids the happening of filament falling off or blocked holes.

Filament Surface Smoothness and Dryness:

Filaments should have moderate surface smoothness and dryness, which ensures the smooth filament tufting process and reduce the malfunctions during the brush production.

Length:

Filament length should confirm to the designed brush specification, satisfying the usage requirements of different brush.

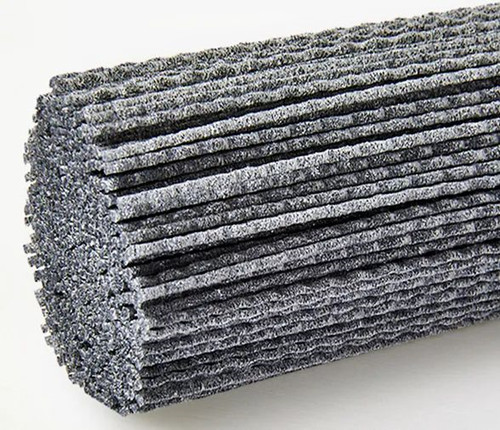

Straight level:

Stable filament straight level increases the tufting efficiency and brush quality.

Wear Resistance and Safety:

Filaments with good wear resistance and bending recovery strength are suitable for making personal care brush products, such as toothbrush, shower brush and interdental brush etc. Importantly, filaments should confirm to the strict safety standard to protect the human health.

High Temperature Resistance:

Filament with heat resistance can maintain the stable performance even in the high temperature environment.

Company Profile:

Tai Hing provides over 4300 product portfolio applied in 12 industries, cooperating with famous brands from Japan, Australia, Europe and USA etc., and getting the worldwide reputation in different industries. From now on, Tai Hing has launched Doclean™, BeautyFil™, GrindFil™, Sentec™, Nevanx™, Lasson™, MaskFit™. We always focus on the research of key materials and technologies in the field of Brush Filament application.

Filament products are widely applied in industrial brush, sanitation brush, household cleaning brush, cleaning brush, Hairbrush, false eyelashes, paintbrush, Plastic Nose Wire industries etc.

Welcome to contact us. Email: marketing1@taihingnylon.com