GrindFil Has Excellent Effect on Automobile Surface Polishing Process

How to Produce the ‘Mirror Level’ Automobile Paint Surface?

Recently, Xiaomi held the special automobile exhibition called ‘Door to Door’ in Pairs, France. This popular special exhibition showcased the automobiles with ecological automotive system.

At the entrance of the special exhibition, there was a SU7 automobile with dazzling sunset purple color parked, which attracted lots of local people and famous car industry insiders to visit. They all expressed highly interest and attention to this amazing car.

Since the release of Xiaomi SU7, its glossy and smooth automobile surface has received much attention. Do you how to produce this smooth ‘mirror level’ automobile surface? It was reported that painting and coating processes were very important during the automobile manufacturing process, which ensured the effect protection for the car body and car components.

Therefore, industrial brushes are widely applied in the automobile surface treatment before coating process. For example, industrial brushes are used to remove the residue on the car surface and polish the surface to ensure the adhesion and uniformity of the coating.

Industrial brushes also have other uses, such as cleaning, coating, sealing and removing static etc. Good quality industrial brushes ensure the consistency between automotive parts and overall vehicle quality, and improve the performance and reliability.

How to choose the suitable filament for making industrial brush? GrindFil abrasive filament is the best fill materials for industrial polishing brush.

GrindFil Abrasive Filament

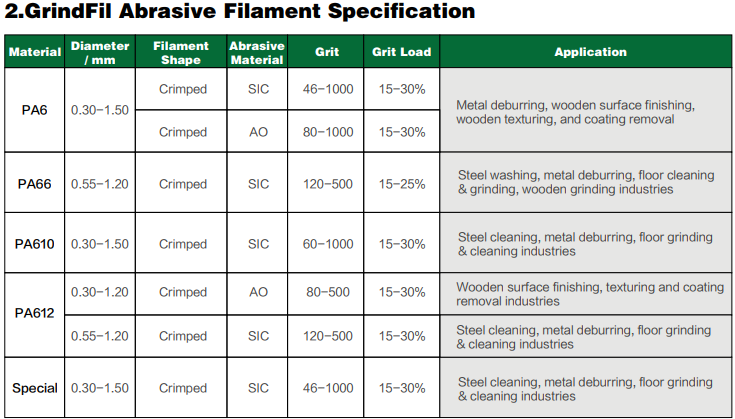

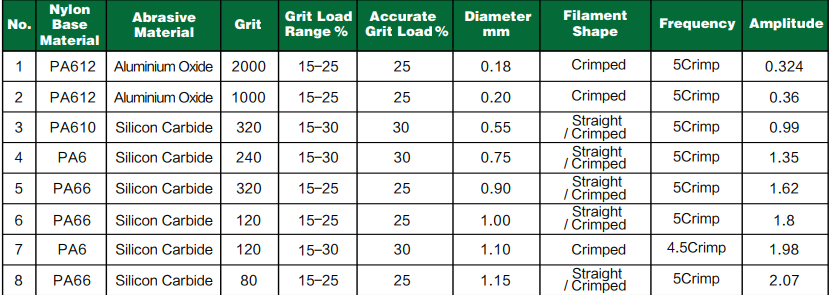

GrindFil abrasive filament is made of high quality nylon6/610/612 raw material and silicon carbide/aluminum oxide abrasive materials.

GrindFil is applied in twist brush, strip brush, belt brush, disc brush, roller brush, cup brush. Besides, GrindFil is also applied in wooden grinding, steel polishing, metal finishing, glass grinding and ceramics grinding industries.

GrindFil Specification:

The whole body of GrindFil, including its outer surface, cross-section and inner core, is randomly distributed by grinding sand to form rough, hard and tiny edges and corners.

When the brushes are driven by the industrial machine at high speed, GrindFil scratches and rubs the metal surface densely, processing the procedures of finishing, polishing, deburring, sharpening and removing the oxide layers etc.

GrindFil can keep outstanding surface finishing effect for a long time, which refers to the flexible grinding processing and it does not destroy the original size of workpieces.

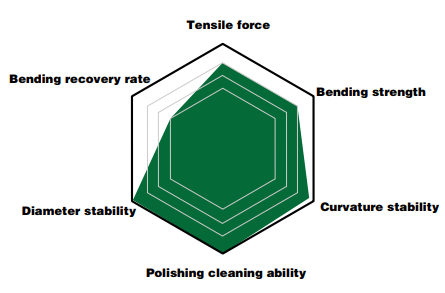

GrindFil Product Performance

Nylon base material has excellent resilience performance. GrindFil always keep straight after use. The monofilament bending recovery rate of GrindFil exceeds 30% after tested by rebound test.

The available diameter range of GrindFil is from 0.3-1.5mm. Filament with uniform diameter has better grinding ability without causing any damage to the workpieces.

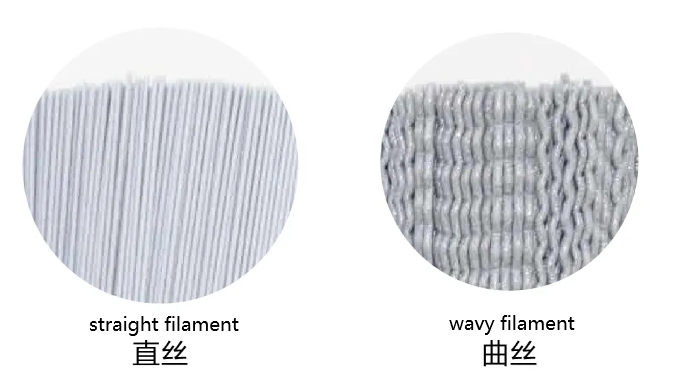

Straight and crimped filament are available and filament shape can be customized based on client’s requirement. GrindFil always keep straight without any deformation in the using process.

The amplitude range of GrindFil is from 0.54-2.7.

The following table shows the specifications & parameters of different kinds of abrasive filament.

If you are interested in GrindFil abrasive filament, please feel free to contact us.

Email: marketing2@taihingnylon.com

Whatsapp/Wechat: +86 18823081172