The Release of Plastic Rubber Pad Comb Group Standard

Plastic Rubber Pad Comb Group Standard Promotes the Development of Hairbrush Industry

In order to help hairbrush manufacturers strictly carry out the plastic rubber pad comb production standard, Tai Hing Nylon Filament Products Co., Ltd., Ningbo RAVO Group and other four leading Chinese hairbrush companies jointly participated in the compilation of Plastic Rubber Pad Comb Group Standard, which helped hairbrush companies produce stable and high quality hairbrush products.

Plastic Rubber Pad Comb Group Standard set many standards of hairbrush, such as the classification, shape, size, hardness, chemical and physical properties, technical standard, testing method and schematic diagram, testing rules and using instructions.

The Group standard successfully offered fair basis for hairbrush market competition, standardized the plastic rubber pad hairbrush production standard and promoted the technical development of hairbrush industry.

Tai Hing actively participated in the compilation of Plastic Rubber Pad Comb Group Standard, in which every point confirmed to the highest standard of hairbrush industry.

Tai Hing set the new quality standard for plastic rubber pad hairbrush production in the aspects of materials selection to the application of innovative technology.

The release of Plastic Rubber Pad Comb Group Standard would help hairbrush enterprises become more competitive in the intense market competition.

Leading Plastic Monofilament Manufacturer with 40 Years of History

As one of the leading monofilament enterprises, Tai Hing has 40 years of filament production experience and strong R&D strength.

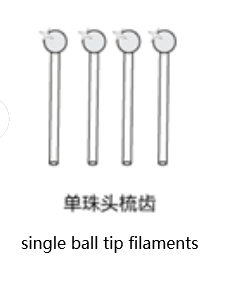

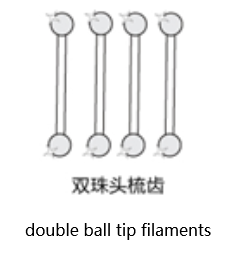

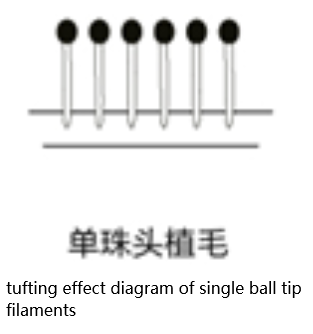

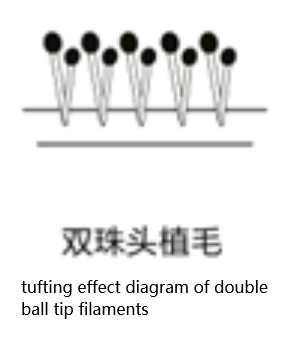

During the Group Standard compilation process, Tai Hing offered many valuable suggestions regarding to hairbrush production. Tai Hing’s team deeply analyzed hairbrush filaments and put forward to accurate filament definition and categories. That not only improved durability of hairbrush products but also upgraded more better using experience for customers.

Tai Hing continuously focus on improving the design and quality of hairbrush filaments and special nylon ball tip fibers, which ensures every filament category satisfies high level standard of customers.

Nexfil™ Nylon Filaments

It is the popular filament choice for hairbrush because of its excellent tensile strength and wear resistance. It not only easily loose hair knot but also effectively reduce static electricity.

Tai Hing continuously carries out strict product production standard and controls all nylon filament quality, which ensure every filament piece has good durability. Besides, nylon filaments can be designed with anti-static/negative ion/antibacterial functions.

We recommend Nexfil™0066 and Nexfil™0046 high temperature resistant nylon filaments for hairbrush products. They all have excellent features of heat resistance and bending recovery strength, suitable for professional salon hairbrush products.

Nexfil™O: Round Nylon Ball Tip Filaments

Through innovative manufacturing technique, Tai Hing has developed high quality Nexfil™O ball tip filaments. Its patent number is ZL 2020 3 0278877.3.

Compared to regular melting ball tip filaments, Nexfil™O has more uniform ball tip shape, which increases the contact area on human scalp and offer comfortable scalp massage feel. It feels like that you are enjoying the scalp SAP massage when you use the hairbrush made of Nexfil™O.

Flexible ball tip filaments loose hair knot easily and make your hair smoother.

Special round ball tip shape is especially suitable for sensitive scalp, providing comfortable scalp massage feel and promoting scalp blood circulation.

Tai Hing adopts new materials and improves the technique of filament surface smoothness and dryness through the test. High-end quality hairbrush nylon filaments are glossy after melting process.

Nylon ball tip filaments are round and there are no any bubbles and holes inside the ball tip shape. Ball tip design has good color fixation, not easy to be yellowed.

Good tensile strength makes ball tip filaments are not easily falling off, which effectively reduces the subsequent processing steps for hairbrush manufacturers and therefore reduces cost.

If you are interested in our hairbrush filaments, welcome to contact us to get more details.

Email: marketing@taihingnylon.com

Wechat/Whatsapp: +86 18823081172