Innovative Abrasive Filament Product: GrindFil Abrasive Filament with Glass Fibre

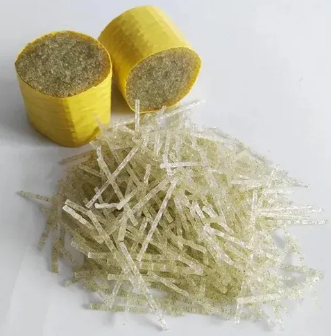

In order to improve the polishing effect of abrasive filaments, Tai Hing successfully has upgraded the manufacturing technology of abrasive fibers and developed GrindFil abrasive filament with glass fibre.

Innovative Manufacturing Technology: abrasive filament with glass fibre

As the inorganic non-metallic materials, glass fibre has excellent performance of mechanical strength, corrosion resistance and insulation properties. Through the advanced manufacturing technology, Tai Hing has successfully produced abrasive filaments, which are made of glass fibre, high-quality PA612/6/610 nylon base materials and high performance abrasive materials(silicon carbide/aluminum oxide/ceramics etc.).

Perfectly merged with glass fibre, GrindFil abrasive filaments not only have better performance of hardness and durability but also maintain the stable performance under complex working environment.

Five Core Advantages

1. Stronger Grinding Strength

High strength characteristics of glass fibre greatly enhances the mechanical strength of GrindFil. Glass fibre abrasive filaments have obvious grinding effect and therefore improve the grinding efficiency during the grinding wood/steel/iron/metal/glass/ceramics process.

2. Excellent Corrosion Resistance

Because of the chemical stability of abrasive filaments made of glass fibre and nylon materials, GrindFil abrasive filaments with glass fibre resist to acid&alkali chemical solution and it will not deform and age in different complex industrial environments.

3. Excellent Bending Recovery Strength

GrindFil added glass fibre improves the bending recovery strength and it rebound quickly after the frequent use or under the high-strength bending condition.

4. Wear Resistance

Traditional abrasive filaments normally tend to wear out over long periods of time. Added glass fibre, GrindFil enhances the wear resistance and keeps ideal performance after the frequent use.

5. Environmental Protection & Efficiency

GrindFil with glass fibre not only enhance the industrial grinding efficiency but also reduce the resources and tool lost, providing more environmental and economical choices for customers.

Suitable for Wide Application

Tool types: twisted brush, strip brush, disc brush, roll brush, cup brush

Applicable material range: wood, steel, metal, glass, ceramics

Application: surface cleaning, precision grinding, polishing to remove rust, deburring etc.

GrindFil abrasive filaments with glass fibre are widely applied in precision manufacturing industry and traditional processing industry.

As one of the leading industrial brush filaments manufacturers, Tai Hing is committed to developing innovative technology to upgrade filament products. GrindFil abrasive filament with glass fibre is the ideal choice for industrial polishing/grinding/deburring industry.

In future, Tai Hing will continue to explore new technology and new materials and develop more innovative high-end abrasive filaments to satisfy customer’s needs.

Welcome to contact us to get more filament details.

Email: marketing2@taihingnylon.com