New Products: Aerogel brush Filaments

In the rapidly advancing field of materials science, novel materials are emerging like mushrooms after rain, bringing unprecedented opportunities for transformation across industries. Among these, aerogel brush filaments, as a highly promising innovative material, are capturing the attention of numerous industries with their unique performance advantages.

Breakthrough Performance through Cutting-Edge Technology

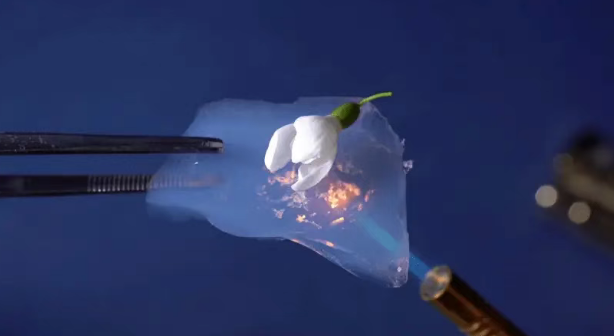

Aerogels inherently possess excellent thermal insulation properties and low-temperature resistance characteristics. Aerogel brush filaments further enhance these properties through advanced technologies, achieving remarkable performance.

Material Composites and Performance Optimization

A. Flexible Polymer Composites: By combining aerogels with highly elastic polymers such as polyimide and polyurethane, the flexibility and wear resistance of brush filaments are significantly improved. For instance, polyimide aerogels can achieve a stretch rate of up to 1250%, meeting the requirements for repeated deformation in brush filaments.

B. Nanotechnology Enhancement: Incorporating nanomaterials like carbon nanotubes or graphene improves mechanical properties, such as increasing compressive strength to more than three times that of traditional materials.

C. Surface Functionalization: Chemical modifications, such as hydrophobic coatings or photocatalytic coatings, endow brush filaments with additional functionalities like self-cleaning and antimicrobial properties.

Process Adaptability

A. Electrospinning Technology: This technique is ideal for producing ultra-fine aerogel fibers with diameters at the micrometer scale, enabling precise control over fiber density and arrangement.

B. 3D Printing for directional molding: Through extrusion-based 3D printing, porous gradient structures can be designed to optimize cleaning efficiency and durability.

Diverse Applications, Exceptional Advantages

The unique properties of aerogel brush filaments make them ideal for a wide range of applications.

Broad Application Fields

A. High-Temperature Industrial Cleaning: In industries like petrochemicals and metallurgy, which operate in environments exceeding 400°C, aerogel brush filaments combined with ceramic or glass fibers can withstand temperatures up to 650°C while maintaining lightweight properties, making them an excellent alternative to traditional metal brushes.

B. Precision Instrument Cleaning: For delicate components like electronic parts and optical lenses, graphene-composite aerogel brush filaments offer conductivity to eliminate static attraction, while their nanoscale pores minimize surface scratches.

C. Medical and Biomedical Devices: Endoscopes and surgical instruments require antimicrobial and residue-free cleaning brushes. Chitosan/aerogel composite filaments provide natural antimicrobial properties and high surface area for efficient dirt adsorption.

D. Environmental Filtration and Oil Spill Cleanup: In oil spill and industrial oil contamination scenarios, cellulose aerogel brush filaments can adsorb oil up to 300 times their own mass and are biodegradable.

E. Smart Cleaning Systems: For robotic or drone-mounted cleaning components, aerogel brush filaments with a density as low as 3mg/cm³ are ideal. They can also be modified for pressure-sensing functions, making them suitable for intelligent cleaning systems.

Collaborating for a Brighter Future

While aerogel brush filaments have demonstrated feasibility through material composites and process innovations, challenges remain in terms of ductility improvement and cost-effective large-scale production. This presents a valuable opportunity for collaboration. We look forward to working with you to advance this new material, overcome technical challenges, and achieve mutual success.

If you are interested in exploring business cooperation with us or wanting to learn more about this innovative material, please feel free to contact us.

Email: marketing2@taihingnylon.com