Breaking the High-Temperature Barrier, Nexfil Filaments Empower Advanced Manufacturing Industry

With the rapid development of industrial automation and precision processing technology, the stability of equipment in high-temperature environments has become a critical factor in determining production efficiency and safety.

Traditional nylon materials tend to soften and deform above 150℃. However, Tai Hing’s Materials Technology, relying on its independently developed "high-temperature resistant nylon" base material, has innovatively launched the Nexfil Brush Filament, featuring a heat deflection temperature of 220-260℃ (±10℃) and superior anti-aging performance. This product redefines the thermal resistance limits of industrial brush filaments, offering a groundbreaking solution for high-temperature applications.

This advanced solution is set to revolutionize the manufacturing industry, providing reliable and durable materials for demanding industrial environments.

High temperature resistance and long-term stability

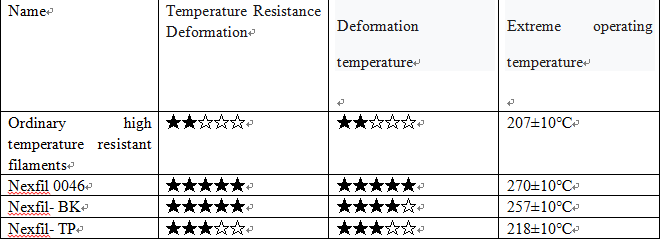

High temperature resistance:

Nexfil retains its stiffness even under high-temperature environment of up to 260℃, demonstrating exceptional resistance to thermal deformation. This remarkable performance makes it an ideal material for industries with stringent temperature requirements. Industrial brushes made from Nexfil exhibit stable and outstanding performance in challenging environments such as high temperature, high pressure, wear resistance, and corrosion resistance. Unlike traditional materials, Nexfil does not degrade with increasing temperature, significantly extending the lifespan of brushes.

This innovative solution not only pushes the boundaries of high-temperature applications but also ensures long-term reliability and durability in demanding industrial settings.

More stars mean better performance

Outstanding Anti-Aging Performance

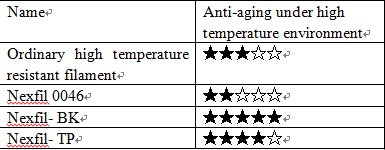

Nexfil demonstrates exceptional resistance to aging, as evidenced by rigorous testing conducted under controlled conditions. Four test samples, including Nexfil, were subjected to a thermal aging test in a constant-temperature oven at 220℃. Every 2 hours, the samples were removed and assessed for signs of aging. The results, as shown in the table, clearly indicate that Nexfil outperforms both conventional high-temperature brush filaments and Nexfil 0046 variant in terms of aging resistance.

This superior performance makes the Nexfil filament particularly suitable for applications in high-temperature environments, such as the cleaning brushes used in food mold manufacturing. Its ability to withstand prolonged exposure to high temperatures without degradation ensures consistent performance and reliability in demanding industrial settings.

In summary, outstanding anti-aging properties of Nexfil make it an ideal choice for industries requiring materials that can maintain their integrity and functionality under extreme thermal conditions.

More stars mean better performance

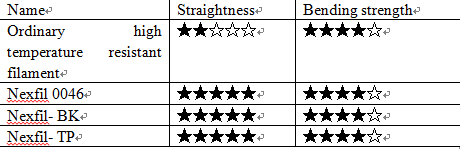

Excellent Bending Recovery Strength&Wear Resistance

Nexfil always keeps good straightness, excellent bending recovery strength and bending strength under long-term high temperature/wet/acid and alkali environment. Low water moisture absorption rate and durability makes filaments be not easy to fall off.

More stars mean better performance

Four main industrial application

Aerospace – The "High-Temperature Guardian" for Precision Instruments

Application Case: Used as brush filaments for cleaning aircraft engine blades, Nexfil withstands high-speed airflow at 300℃ to continuously remove carbon buildup, ensuring turbine efficiency.

Value Proposition: Replaces metal brush filaments to eliminate spark risks, achieves a 30% weight reduction, and contributes to improved fuel efficiency.

New Energy Vehicles – The "Durable Choice" for Power Systems

Application Case: Integrated into the motor brush cleaning system, High-Temperature resistant Nexfil withstands localized temperatures of 250℃ within the electric drive unit.

Value Proposition: Extends service life to 30,000 hours and meets the stringent requirements for insulating materials in 800V high-voltage platforms.

Oil and Gas – Expert in Harsh Pipeline Conditions

Application Case: Used as a high-temperature pipeline cleaning brush for refinery oil pipelines, Nexfil withstands long-term exposure to acidic media and 180℃ hot oil.

Value Proposition: Achieves a 60% improvement in corrosion resistance, a 45% reduction in annual maintenance costs, and eliminates pipeline blockages caused by filament breakage.

Electronics Manufacturing – Precision Partner at the Micrometer Level

Application Case: Used as polishing Brush Fiber for semiconductor wafer polishing, Nexfil maintains a deformation precision of 0.01mm in polishing solutions at 200℃.

Value Proposition: Achieves surface roughness control of Ra ≤ 0.1 μm and boosts yield rates to 99.98%.

High-Temperature resistant Nexfil with its exceptional performance shines brightly as a unique solution in the plastics manufacturing industry. Its unparalleled heat resistance provides dependable and effective solutions for various temperature-sensitive industries.

If you're searching for a material that can reliably perform in high-temperature environments, High-Temperature resistant Nexfil is absolutely trust-worthy.

Email:marketing@taihingnylon.com