The Hidden Value of Industrial Brush Filaments

In manufacturing, the choice of brush filaments can greatly impact costs and efficiency. Our plastic filaments—Nylon 66, PS, and PBT—play a crucial role from wheel hub production to chip assembly.

Nylon 66: The High-Temperature Champion

Nylon 66 withstands a lighter’s flame for 10 seconds without damage. In tests, it keeps 90% of its sharpness after 20,000 uses. On an 80°C paint line, it lasts three times longer than standard brushes, saving around $20,000 annually.

PS Filament: The Corrosion-Resistant Solution

PS filaments remain strong even after three days in hydrochloric acid. They last six months in caustic soda pipelines—double the lifespan of regular filaments. This leads to a 40% reduction in cleaning time and can save petrochemical plants up to 60% on maintenance costs.

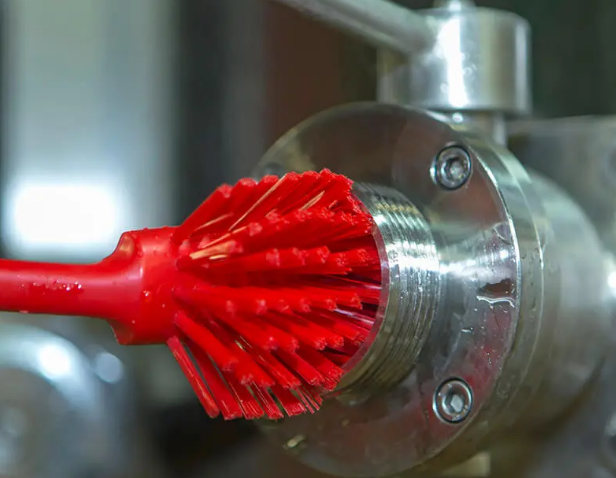

PBT Filament: The Flexible Precision Tool

PBT filaments have a triangular tip that easily fits into 0.2mm gaps, reducing dust by 70%. They can bend 1,000 times a day and return to shape after three months, lasting five times longer than standard brushes—ideal for delicate cleaning tasks.

The Cost of Mistakes

Choosing the wrong filament can lead to major losses. One auto parts manufacturer faced 12 production stoppages in three months due to brush failures, resulting in repair costs eight times higher than quality brush investments.

Quick Tips:

l Use Nylon for High Temperatures: Sturdy up to 180°C.

l Choose PS for Corrosive Environments: Chemical and oil resistant.

l Pick PBT for Tight Spaces: Flexible and precise.